The COVID-19 pandemic has caused havoc for many supply chains around the world. But what have we learnt from the pandemic? How can organizations ensure their supply chains are agile and adaptive enough to respond quickly and successfully to any changes in the market? We spoke to Carl Loubser, supply chain expert and Senior Business Partner at CCi, who shared the following insights.

What have we learnt from the COVID-19 pandemic over the last few months?

While a few industries, such as online retailers, frozen food and tech that enables virtual work, have prospered due to their existing positioning, many industries have had to adapt to significant uncertainty and disruption. Enterprises that can easily transition into new markets with new offerings and those that are agile to volatility in market demand and can make the operational adjustment and alignment are best set for continued success.

The triple A (of 4As) from Hua L. Lee (see below) is even more insightful now:

- Agility is critical in most organizations where demand or supply fluctuates rapidly or widely. It is especially on the demand side that the ability to respond to upside and downside-swings has to be built into the supply chain in order to respond quickly and cost effectively.

- Adaptive supply chains are those where the organization can adjust its network (upstream and downstream) to allow for strategic shift or market changes. The best supply chains are those where structural shifts are firstly identified early, and secondly are able to respond appropriately to these shifts.

- Aligned supply chains are those where the interest of all (or at least most) of the supply chain partners are aligned. Where conflicting priorities exist internally between functions, and externally with supply or distribution partners, the overall performance will suffer.

- Architecting – build different supply chains for different requirements, but ideally fit them over the ‘platform’ to minimise cost and complexity. Strive for value and social responsibility.

In particular, as noted above, rethinking architecture of the overall value chain will create tighter synchronization across all supplier bases and with differentiated customer segments.

For supply chains, once the initial crisis containment actions were put in place, it became a time of reflection. What will this mean in the short and medium term?

In my opinion, the focus will be a mix of the following:

- Continued cost reduction and a more critical look at capital investment

- Focus on Integrated Business Planning (IBP) – demand insight (response-time from insight to action)

- Product simplification

- Streamlined ways of working – virtual teams and remote work can work, and in manufacturing environments spacing may continue to be mandatory for some time, so companies will figure out how to forge efficiencies, for example through increased automation

- Lead time ‘stretch’, i.e. offerings with a longer supply lead time, but with greater reliability (this is a bit counter-intuitive)

- Increased digitization to improve total cycle of service to offset the above – so quicker ‘administrative and processing’ response

- Collaborative insight and increased risk sharing along supply chain partners (especially in deflation/low inflation environments)

- Agility though delayed customization and reduced product portfolio

Following on from the previous question, what will this mean in the longer term?

There will be a key focus on supply chain continuity. Where companies have perhaps become too focused on cost reduction and working capital reduction (Total Cost to Serve), there will be a more conservative approach in the dependence on single suppliers, lengthy supply chains, and a too biased view on volume growth. This will result in stronger supply chain connectivity and more standardization to maintain the cost to consumer.

There will also be a focus on:

- Increased digitization to minimize waste (process input and processing time) to improve service and decision-making along the supply chain

- Re-assessing route-to-market channels. In many industries e-commerce has been a savior. There will be some rebalance to pre-COVID-19 norms, but digital commerce will retain impetus

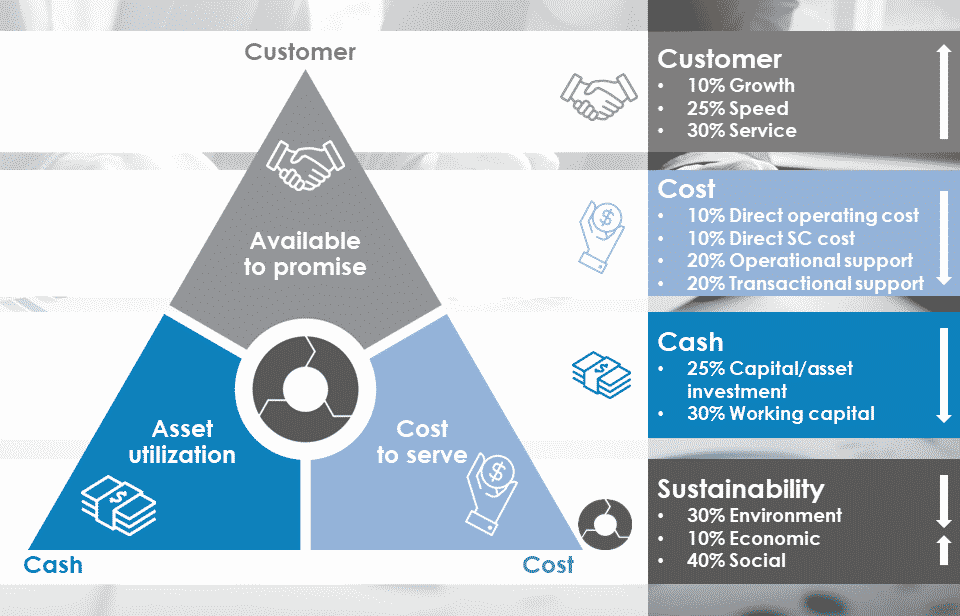

- More balanced decision-making and target setting:

Results you can achieve

For some time now, Gartner has suggested that the role of the supply chain should be bimodal. Supply chain professionals must focus on operational execution as well as growth. How should this be done?

For some time now, Gartner has suggested that the role of the supply chain should be bimodal. Supply chain professionals must focus on operational execution as well as growth. How should this be done?

The ability to achieve these dual objectives stems from the same foundations:

- Ability to understand and read market needs

- Be agile and responsive to those needs

- Create reliable and cost-effective execution of the need fulfilment promise – this need is greater now than ever

- Increasing competition

- Increasing customer awareness

- Evolving customer expectations

- Speed of technology adoption, especially to improve end-to-end visibility

- Greater internal expertise, pressure and therefore functionalization – resulting in silos

The dual objectives will only be achieved with an operational excellence framework that will anchor collective improvement efforts and align all operational functions.

What will reinforce global competitiveness?

Extending the idea of bimodality, re-strategizing how to strengthen supply chain foundations whilst also renewing innovation. Successful companies always look to the future, and the pandemic’s lasting effect will be a quickening of disruptive change. At the same time, rigorous and proven practices have never been more important. In that sense, nothing is new.

Economies of scale will be driven through:

- Purchasing power

- Network efficiencies

- Risk mitigation

Reputation and reach must incorporate:

- Trusted partnerships

- Brand value

- Global, but local

Leverage of skill should include:

- Leverage of asset base

- Leverage of learning

- Systemization of continuous improvement

“How do we do everywhere what we do well somewhere?”

The COVID-19 pandemic has highlighted the significance of ensuring your supply chain processes are robust and resilient enough today to remain globally competitive and adjust seamlessly to any major upsets in the market of tomorrow.

Read Recovery and resilience: Safeguarding and strengthening the supply chain to thrive through uncertainty for more insight into actions required to insulate and bolster short-term robustness and strengthen longer-term supply chain resilience.