Beam Suntory, the world’s third largest premium spirits company, boasts an award-winning portfolio that includes Casa Sauza’s Sauza Tequila — ranked number 26 on the world’s top 100 premium spirits list. In 2014, the Beam Suntory TRACC journey began with a formal assessment at all its plants, after which the Leading and Managing Change TRACC was implemented globally. The objective was to simplify the operations and supply chain processes, specifically the processes that were common to both functions: distillation, warehousing and bottling.

As a result, numerous improvement projects were undertaken. One such project at the Casa Sauza distillery in Mexico has produced some hard savings, making it the plant with the lowest costs in the Americas. Here is their story.

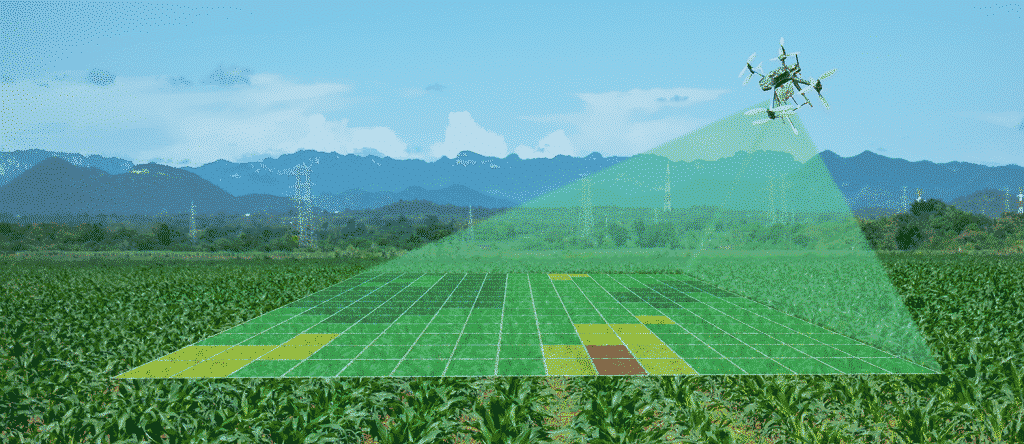

The ‘Drone mapping for agriculture’ improvement project

For over 400 years, the labor intensive craft of the agave harvest remained mostly unchanged. Every generation of jimadores, Mexican farmers, counted, selected and cultivated ripe agave, a large succulent plant with a pineapple-like center used as a raw material in the production of true tequila. Calculating how many agave plants were growing in the fields has traditionally been a lengthy process, often taking up to six months. In addition, while the global demand for tequila has risen, the number of youths interested in becoming jimadores is steadily decreasing.

Drone technology and artificial intelligence are offering sustainable solutions to these considerable challenges — as is evidenced by Casa Sauza’s award-winning improvement project which was presented to Suntory Group President Takeshi Niinami in 2017.

The project involved the use of drones to get an accurate inventory of the agave plants in the fields and to reduce the time it takes to complete this inventory. The drones are relatively easy to deploy and equipped with specialized cameras.

The process works as follows:

- An agave field map gets imported into e-motion software. This map shows details of the agave fields such as their location, number and size.

- Drone flight plans based on topography and objective are mapped out. The purpose of these flights is to take photos of the agave fields for inventory counting.

- The drone is thrown into the air. It is monitored and if anything goes wrong during its flight, people on the ground are on standby to land it.

- The photos taken during the drone flight are converted into images with coordinates to track their location.

- An artificial intelligence process is applied to ensure only agave plants, and no stones or weeds, for example, are counted. The process uses an algorithm that puts silicone into each plant that is identified as an agave plant. Another algorithm counts the silicone, which then provides the total agave inventory.

- The inventory data is loaded and tracked in the Sauza Blue Harvest application, and later transferred to SAP for SKU tracking.

Besides saving time and counting inventory, the drone technology is also used to manage, monitor and increase crop productivity, and to assist in diagnosing the health and vitality of the agave plants.

The agave inventory counting process has produced some remarkable savings. Firstly, the process is much faster as it was reduced from six months to one month. In addition, it is 73% cheaper than the previous labor-intensive process. This achievement is the result of the 60% reduced labor cost, no transportation costs, 91% less depreciation, no government taxes, no food and travel expenses, and 77% fewer days of activity.

Potential accidents and injuries were reduced by 99%. The environmental impact was also reduced as the consumption of 8 100 litres of gasoline was avoided. Developing strategies in advance also created a more proactive workforce.

How Beam Suntory achieved these results

The Leading and Managing Change TRACC was introduced globally at numerous Beam Suntory plants. At Casa Sauza distillery in Mexico, teamwork practices were implemented to empower and upskill employees. Each employee is encouraged to present at least three improvement projects at a yearly fair where the best project is rewarded and presented to the Suntory Group President in Tokyo. Reward and recognition therefore incentivises employees to find new solutions to old ways of working.

When it came to employees who are most proud of their company, Casa Sauza was ranked the highest by its employees. The plant also won second place in a ‘great place to work’ survey by the Great Place to Work Institute in 2017, when they were competing with companies like Nike in the category of companies with less than 500 employees in Mexico.

A continuous improvement culture is now the driving force behind Casa Sauza’s daily operations. Employees feel empowered to take decisions, offer suggestions and present their improvement ideas. The reward and recognition programme has provided the incentive, and it has also infused the improvement culture with the energy and momentum necessary to ensure employees continue investigating more efficient and cost effective solutions.