It is possible to get excited about cost-cutting. Even as recession bites or looms in most markets around the world, with corporate bottom-lines devastated by the extraneous factors implicit in the COVID-19 crisis, the management of costs should be more than crisis management.

Before the pandemic struck, many industries already faced enormous challenges, such as changing consumption patterns and rising teetotalism impacting the alcoholic beverage sector, or the repercussions of the sharing economy’s transportation and mobility trends for the automotive industry. Best practice disciplines will continue to forge operational excellence, strengthen end-to-end supply chain bonds, and build an organization’s resilience. But the rules have altered, and companies should view the current paradigm not as a hiatus before returning to normal, but as a juncture to re-engineer the business ecosystem, to improve operations, and to accelerate transformation plans.

This requires a strategic approach to cost management

World-class companies view costs as inputs to drive current and short-term revenue growth and innovations to sustain these in the medium- or long-term horizon. Return-on-investment (ROI) achievement requires the investment, part of which are table-stakes or open-for-business, ongoing costs. But it’s the management of these costs – their transparency and consistent interrogation – which sets the bar and differentiates cost line-items and their levels across the spectrum of effectiveness or redundancy. In short, the optimization of cost reductions occurs when it achieves tighter alignment between the company’s strategy and its execution.

This requires an enterprise-wide assessment of costs, across all divisions and throughout the value chain. The objective is to improve all-round enterprise effectiveness – operationally, in terms of customer satisfaction, employee engagement, and returns. Fine-tuning budgets to allocate spending where it can strengthen key initiatives supports the principle of a relentless commitment to CI. This will safeguard the business’s ROI in the near-term and future-proof it for the longer haul.

Prioritizing and trading off efficiencies versus effectiveness

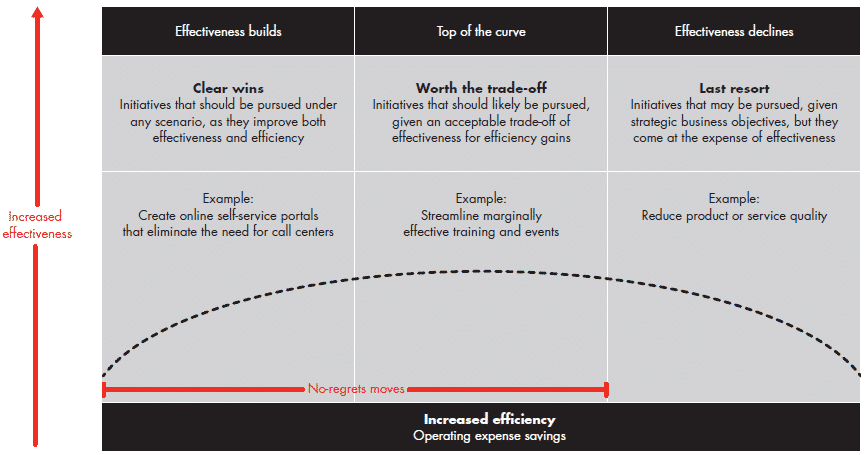

To synchronize cost management with business improvement, categorize potential re-allocable or removable items according to what Bain & Company call the effectiveness curve. By analyzing both the degree of delivered efficiency (spending reductions) and effectiveness (improved outputs), proposed reductions can be grouped into either ‘clear wins’, ‘worth the trade-off’, or ‘last resort’ cuts.

The effectiveness curve

Source: ‘Digital lean: a guide to manufacturing excellence’, Bain & Company, 2019

Consider maintaining initiatives at lower cost by collaborating with business ecosystem partners facing similar dilemmas. Or, assess whether outsourcing of selected projects will save costs – and even, feasibly, quicken fulfilment timelines.

Now is the time to investigate the company’s true state of lean

Lean principles by definition aim to instill organizational efficiency across all functions, with ongoing disciplines and improvement techniques. The company’s production system should be TPM-geared for world-class manufacturing performance and quality, including autonomous maintenance, training, and focused improvement levers and initiatives. But how deep does the principle hold in this tumultuous time, when the value chain faces enormous challenges on both the demand and supply sides, and with cost constraints needing to be balanced with recovery plans?

Production performance, loss and quality KPIs must now be revisited and strategically redefined, and the status of 5S established and reinforced if necessary. Apart from maintaining focused improvement initiatives as a pillar of TPM, give attention to two further key areas:

1. Target total waste elimination

Production waste and process redundancy should be on the radar for tightened protocols. Power-, energy- and water-saving policies must be created and adhered to. Green principles not only save money, but embed a sustainable practices culture within the company.

The scope for savings is illustrated in Unilever’s Sustainable Living Plan. Launched in 2010, in the ensuing decade the company claims it has delivered a cumulative €1 billion in cost avoidance through improved energy and water efficiencies in factories, reduced materials usage and waste cuts. Both Unilever and rival consumer products giant Nestlé aim to make all their packaging reusable or recyclable by 2025; these ambitious goals do not necessarily need to be matched, but setting an organization’s targets for the circular economy agenda will drive improvements and productivity savings.

The range of other feasible improvements in this ambit is vast. Although a basic and routine requirement of TPM, an urgent maintenance audit may be deemed appropriate: machinery and equipment that doesn’t function optimally causes waste and cost over-runs. At a more complex level, an audit of raw material sourcing costs may be opportune. COVID-19 has highlighted the inherent risks of dispersed, just-in-time (JIT) global supply chains, and it may be revealing to analyze comparative risks and logistics of a nearshoring alternative. The raw material input may be more expensive, but the holistic sourcing cost may be reduced – and reputational relationships with local communities and customer bases may be enhanced. The trade-offs between unit material costs, systems efficiencies, and logistics savings should be interrogated as part of end-to-end supply chain visibility and cost comparisons.

10-point checklist to align costs to strategy

- Take an enterprise-wide view, not divisional or functional.

- Zero-base. Scrap the ‘last year plus a percentage’ budgeting framework. Re-evaluate costs based on their necessity in delivering the company’s value proposition and enabling competitive capabilities.

- Have all processes and systems been evaluated for agile and flexible capabilities? These attributes forge resilience, and decision-making speed enables improvement throughout the value chain.

- Streamline, cut or outsource underperforming systems or projects. CI requires consistency, and focused improvement demands exactly that – focus.

- Benchmark. Have key performance areas been targeted against goals, referencing internal benchmarks, industry averages, and specific leading competitor data?

- Are layers of cost complexity reduced?

- Does the strategy include a plan to accelerate automation?

- Invest in technologies which improve visibility, data accessibility and decision-making support tools such as predictive analytics.

- Empower cross-functional teams to identify and implement improvement measures and profit improvement projects. This will foster a permanent cost awareness and feedback culture.

- Look forward. As a crisis response, cost-cuts have been necessary. Now, make the exercise iterative – a regular review of efficiency and effectiveness reinforces the discipline of improvement.

Stripping out waste and redundancy can also be aided by data analytics tools. Significant performance and productivity improvements are feasible in logistics, for instance, using warehousing systems which synthezise with ERP data to streamline warehouse processes, and traffic- and GPS-location optimization applications which reduce travelling distances, waiting times and fuel costs for trucking companies. United Parcel Services (UPS), for example, claims to save up to $400 million per year through the data-driven efficiencies of Internet-of-Things (IoT) applications which optimize navigation across its 55 000 customer routes in the US alone.

2. Harnessing technology is crucial to leveraging improvements

In plants and on factory floors, overall equipment effectiveness (OEE) is significantly improved by traditional lean practices, but the level of improvement can be amplified by digital technologies – by as much as double, according to some studies.1

As such, resist the inclination to shelve investment plans for expanded automation. Payback period for such investments will be comparatively quick: the cost of robotic technologies has halved in the last 25 years, and the worldwide trend is that prices will continue to fall. In contrast, the labor cost curve is rising.

In wider supply chain and SOP processes, data-driven applications and tools must be leveraged to greater potential. For instance, a deeper understanding of suppliers’ cost structures can re-gear procurement processes to improve competitive positionings and purchasing decisions. The reverse applies: data-rich analyses can shed light on the customer landscape, which may be invaluable to drive margins through demand-shaping, pricing or customer segmentation.

Initiatives to transform technology capabilities can involve complexity. Streamline, integrate and simplify wherever possible: Gartner calculates potential savings of up to 30% on software costs through asset management tools which optimize the configuration of applications and related licensing.

Global leaders balance resilience through crises with readiness to capitalize beyond it

The immensely challenging period triggered by COVID-19 will be a platform for driven companies to deepen competitive capability and advantage. Their leadership and management teams will prioritize cost cuts as part of the iterative improvement process – seeing an opportunity to negotiate win-win scenarios with major suppliers by extending contracts in return for improved discounts; or scrutinizing the R&D pipeline to rationalize the number of projects in the short term but boost investment behind the blockbusters backed to drive revenues in the next 5-10 years.

Beyond the understandable scramble to slash discretionary spending, a broader view is to contextualize the organization’s costs towards the refocused, renewed challenge of 180-degree disruption. Identify those good costs – those which will drive continuous improvement, sustain ROI, and consistently beat the industry’s cost curve. Evidence from previous recessions indicates that companies which maneuver to avoid deep structural cuts to workforce and systems costs, working capital and investments, outperform competitors post-recession.2

Leading companies cut costs not because they have to, but with the objective of becoming better.

1‘Digital lean: a guide to manufacturing excellence’, Bain & Company, page 8, figure 4: combining digital and lean initiatives can reduce costs by up to 30% vs. 15% for traditional lean efforts.

2In ‘Roaring Out of Recession’, Harvard Business Review, March 2010, a study of 4,700 companies in different periods of recession and recovery.