Key takeaways

- Continuous improvement focuses on improving all the processes, practices, products and services of an organization

- The key questions about continuous improvement answered

- Eight blog summaries that outline how CI applies to your organization

30 January 2023 – Continuous improvement (CI) is how leading manufacturers maintain their competitive edge while navigating ongoing economic uncertainty. Find out more about what it is and how to measure it, the benefits it can bring your organization, where to start your CI journey, and how to ensure its success below.

What is continuous improvement?

CI focuses on improving all the processes, practices, products and services of an organization. It requires ongoing efforts and while it is often realized through small, steady and incremental improvements by frontline workers (kaizen methodology), big breakthrough improvements are also possible.

A world-famous example of a CI approach in action is the Toyota Production System (TPS). The global manufacturing industry holds the TPS in high esteem – and for good reason too. Its lean philosophy underpins an efficient methodology that reduces waste and thereby creates more value.

The result is an entire organization working together to continuously improve the way it works to ensure superior customer satisfaction.

Why is continuous improvement important?

The arrival of advanced technologies such as artificial intelligence (AI), automation, machine learning, data analytics, the Internet of Things (IoT) and robotics has transformed manufacturing operations. As a result, organizations have had to digitalize their operations and move from a traditional, function-focused production system to a modern, digital operating system (DOS).

A DOS is the next generation in production systems specifically geared to support digitally transformed or transforming manufacturing operations. It’s designed to merge lean and smart principles for ultimate efficiency and agility.

In this digital age, a continuous development approach is more important than ever before. Digital transformation is a complex organizational transition. With a CI culture firmly in place, manufacturers can position the shift to a DOS as positive change and encourage holistic buy-in through inclusive improvements and innovations.

This enables them to mitigate disruption, remain competitive throughout the digitalization process and achieve sustainable success.

How does continuous improvement work?

For CI to succeed and strengthen an organization’s competitive position, it needs all employees to be involved and working together toward the same goal. To create a CI culture, organizations need to:

- Ensure a committed leadership

- Involve and empower their employees

- Recognize the value of incremental improvements

- Focus on the customer

- Measure improvements

- Share ideas, collaborate and celebrate successes

How leaders lead is a crucial component of CI. As such, there needs to be a shift in leaders’ focus from running the business “as a boss” to improving the business “as a colleague”. Continuous improvement models are brought to life and sustained by leaders who, through their own behaviors and actions, encourage their teams to embrace positive change.

There is a method to activating a continuous development approach and maintaining momentum. Organizations can use these six steps to integrate CI processes into their operations. CI needs to be sustained in a continuous cycle; organizations move seamlessly from step 1 to step 6 and back to step 1 to ensure that efforts are ongoing.

What are the benefits of continuous improvement?

The primary benefit of CI is that it improves an organization’s resilience. It achieves this through a range of other benefits that impact the business.

- Operational excellence – Products and services that anticipate customer needs, resulting in better customer service

- Competitive advantage – Improved flexibility and responsiveness by streamlining all processes

- Employee engagement and empowerment – A proactive learning culture that encourages everyone to keep up with new technologies and trends, share knowledge and drive innovation

- Reduced costs and wastes – Increased revenue

- World-class maturity and capabilities – Successful digital transformation with limited disruptions during the transition

- Quality management – Fewer defective products and production errors

How do you measure the benefits of continuous improvement?

The impact of CI efforts is measured in tangible outcomes that directly affect a manufacturer’s bottom line. These key performance indicators (KPIs) can apply to various business objectives in the following ways:

- Production costs (such as volumes of water consumption)

- Employee health and safety (e.g. Number of factory floor incidents)

- Quality control (Amount of defected product returns)

- Customer satisfaction (Customer retention)

- Reputation (Customer acquisition)

- Competitiveness / market position (Time to market)

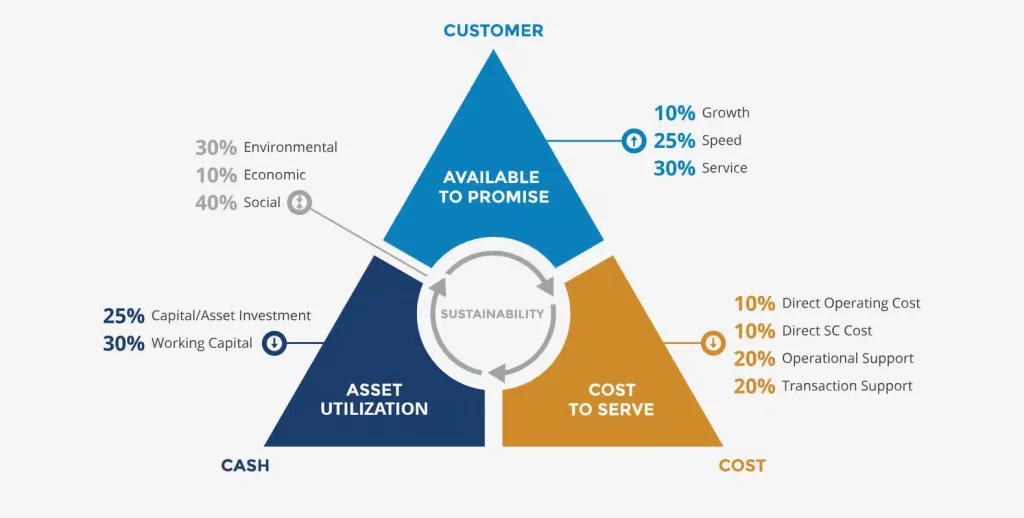

Every organization will have its own set of KPIs that relate to its particular set of objectives. However, success can be broken down into three business segments: Customer, Cost and Cash.

Typical ROI achieved through an integrative CI solution

How do you ensure the success of your continuous improvement approach?

CI efforts succeed when the idea of improvement is embedded into an organization’s cultural DNA. Encourage employees at all levels to look for and implement incremental improvements – this will inspire employee engagement. When employees are encouraged and empowered to innovate, they are much more motivated to put effort into making improvements.

Organizational leaders play a vital role in creating a culture of CI. Their actions, behaviors and commitment to CI influence employee confidence and buy-in. How leaders approach CI will determine their success at inspiring it among their teams, which ultimately determines the organization’s overall level of CI success.

It is a large responsibility but fortunately, leaders can follow these eight focus areas to inspire and guide their teams.

What is the connection between integrative improvement and continuous improvement?

An integrative approach to CI is designed to ensure that improvement initiatives include everyone and impact the business as a whole. It supports the shift to a DOS by dismantling operational silos and integrating teams for faster, better results. Essentially, an integrative improvement approach:

- Arranges an organization around end-to-end processes that serve customer segments rather than functions

- Involves all employees who work together to improve processes and systems from day to day

- Ensures committed leadership that actively encourages the right mindset and behaviors to support integrative improvement principles

- Embeds CI into the culture of the organization